Stone Spider – The largest Stonepower drilling rig

Stone Spider crawler drill is an excellent solution for stepped excavation, bolting or natural stone quarries.

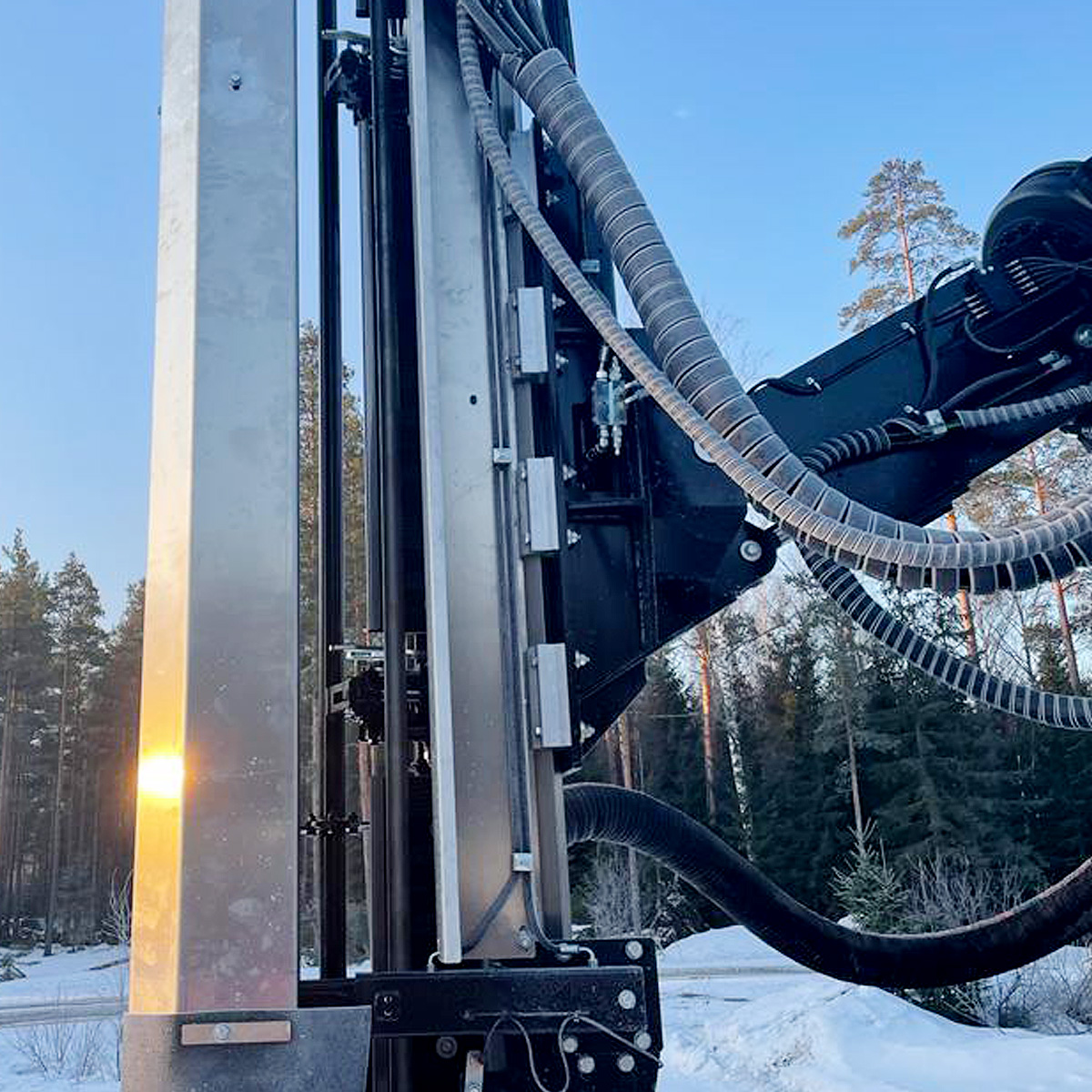

Stone Spider is the biggest of all the Stonepower crawler drills. It maybe the biggest in Stonepower family but in comparison with other similar products it is very compact. A 14.5 ton crawler drill with tracks and 350° turning superstructure is capable to drill also in tight drilling targets.

Turning superstructure is a key factor in increasing the work efficiency. There is a considerable less need to move the crawler thanks to turnability of the superstructure and wide boom coverage. But when it is is necessary to move, tracks, oscillation and a good stability make it safe to move the drilling rig.

It is also easy to move the crawler drill further to another construction site, because its transportation height is only 3.2 m.

Spider has 6-cylinder engine with 175 kw power. Cummins has successfully put a lot of effort in fulfilling the newest environmental standards.